7 Advantages of Supersonic Separators

Supersonic separation technology has emerged as a highly efficient and innovative solution for natural gas processing, offering several advantages over conventional methods. This cutting-edge technology is rooted in the principles of gas dynamics and thermodynamics, which leverage the behavior of gases at supersonic speeds. By rapidly cooling gas flows through convergent-divergent nozzles, separating condensed droplets, and using cyclonic forces, this method presents numerous benefits for the energy industry. This article will explore the key advantages of supersonic gas separation, focusing on its applications in natural gas dehydration, heavy hydrocarbon extraction, and offshore processing.

1. Efficiency in Gas Dehydration

One of the primary applications of supersonic separators is the dehydration of natural gas. Natural gas typically contains water vapor, which can lead to the formation of hydrates or contribute to corrosion in pipelines. Traditional dehydration methods such as absorption, adsorption, and membrane separation, though effective, come with challenges including high operational costs, energy consumption, and complex setups.

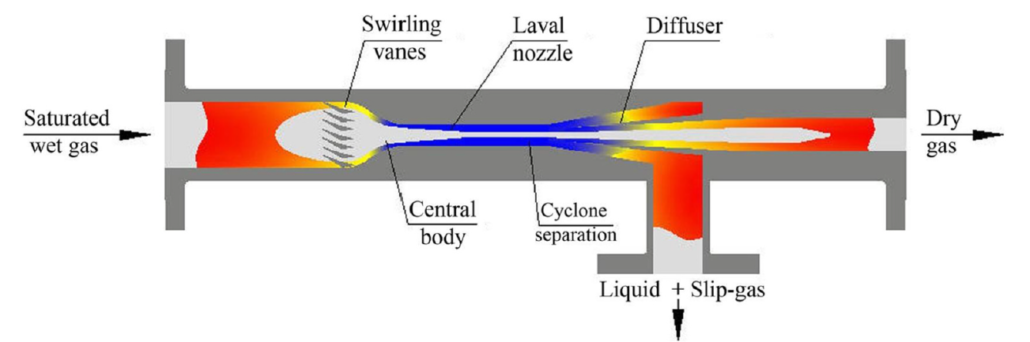

Supersonic separation technology, on the other hand, offers a highly efficient alternative. In this process, gas is cooled rapidly in a supersonic nozzle, causing water vapor to condense into droplets. These droplets are then separated using centrifugal forces in a swirling flow, leaving behind dry gas. This method requires no chemical additives or external energy inputs for heating, making it significantly more energy-efficient. It also minimizes the risk of hydrate formation, as the gas resides in the supersonic separator for only a few milliseconds, reducing the need for hydrate inhibitors like ethylene glycol.

2. Compact and Lightweight Design

One of the most significant benefits of supersonic separators is their compact and lightweight design. Traditional gas processing equipment, such as glycol dehydration units or refrigeration systems, tend to be bulky, require extensive space, and come with a high energy footprint. In contrast, supersonic separators integrate several stages of gas processing into a single, compact unit. This makes the technology particularly suited for offshore and subsea installations, where space and weight constraints are critical.

The compact design of supersonic separators not only reduces the overall equipment footprint but also lowers capital and installation costs. For offshore applications, where deck space is a premium, supersonic separators offer a streamlined solution, reducing both the complexity of the installation process and the operational costs associated with maintenance and energy consumption.

3. No Moving Parts – Minimal Maintenance

Unlike traditional gas separation equipment, supersonic separators operate without any moving parts. This design feature greatly enhances the reliability and longevity of the system. Traditional equipment such as compressors, turbines, and expanders require regular maintenance and are prone to wear and tear due to their mechanical components. In contrast, supersonic separators rely purely on the physics of high-speed gas flow, which significantly reduces the need for routine maintenance.

This “no moving parts” design is particularly advantageous for remote or offshore installations where maintenance operations can be logistically challenging and costly. Operators can rely on the consistent performance of supersonic separators without the need for frequent human intervention, thereby improving the overall cost-effectiveness of the technology.

4. Cost Savings in Operation and Maintenance – SuperSonic Separator

Supersonic separators offer substantial cost savings, both in terms of operational expenses and capital investment. Traditional methods of natural gas dehydration and heavy hydrocarbon extraction require large, energy-intensive equipment, complex systems, and significant human intervention. Supersonic separators, due to their simplicity and compact design, offer lower initial capital costs. Additionally, the absence of chemicals like ethylene glycol, coupled with minimal energy requirements for cooling and separation, further reduces the overall operational costs.

One of the notable advantages of supersonic separators is their ability to conserve reservoir energy. By effectively cooling the gas and recovering pressure in the diffuser section, these separators optimize the energy use of the gas stream, ensuring that more energy is retained within the gas for downstream processing or transportation. This translates to long-term energy savings, particularly in applications such as offshore gas processing, where energy efficiency is crucial for maintaining economic viability.

5. Superior Performance in Heavy Hydrocarbon Extraction

Supersonic separators excel at separating heavier hydrocarbons (C3+, C5+) from natural gas. These components can condense out of the gas stream under the supersonic cooling effect within the nozzle. Unlike traditional methods that rely on complex cooling and separation processes involving multiple stages and chemical additives, supersonic separators use rapid cooling and centrifugal forces to achieve high separation efficiency in a single stage.

Experimental data have demonstrated that supersonic separators can achieve superior performance in hydrocarbon recovery compared to conventional methods such as Joule-Thomson (JT) valves or turboexpanders. For instance, under certain conditions, the recovery of heavier hydrocarbons using supersonic separators can be 10-20% more efficient than with JT valves. This enhanced performance makes the technology particularly valuable for gas processing facilities aiming to maximize liquid hydrocarbon extraction, such as in liquefied petroleum gas (LPG) production.

6. Environmentally Friendly Operation

In addition to cost and performance benefits, supersonic separators offer a more environmentally friendly alternative to traditional gas processing methods. Many conventional gas dehydration and separation technologies rely on chemical additives or energy-intensive processes, which can result in higher greenhouse gas emissions or the release of hazardous chemicals into the environment.

Supersonic separators operate in a closed, chemical-free system. The absence of chemicals such as glycol or methanol reduces the risk of environmental contamination. Furthermore, the compact and energy-efficient design of the system contributes to lower overall emissions, aligning with the industry’s increasing focus on sustainability and reducing carbon footprints.

7. Versatility in Applications

The versatility of supersonic separators makes them suitable for a wide range of applications in the natural gas industry. They can be used for gas dehydration, heavy hydrocarbon extraction, and CO2 removal, as well as in the production of liquefied natural gas (LNG). Their ability to operate under both high and low pressures further extends their usability across different processing environments.

Additionally, supersonic separators are highly adaptable to both onshore and offshore installations. Their compact design, ease of automation, and minimal maintenance requirements make them ideal for challenging environments such as offshore platforms and subsea installations, where traditional gas processing equipment may be impractical or too costly.

Conclusion

Supersonic separation technology represents a major leap forward in the efficiency, cost-effectiveness, and environmental sustainability of natural gas processing. With its ability to deliver superior dehydration and hydrocarbon separation performance in a compact, reliable package, this technology is poised to become a key tool in the future of natural gas treatment. Its versatility and low maintenance make it particularly suitable for offshore and remote installations, where traditional equipment may falter. As the energy industry continues to prioritize sustainability and cost savings, supersonic separators are likely to see increasing adoption across a range of applications.

References:

– Article: Supersonic separation technology for natural gas dehydration in liquefied natural gas plants; by: Jiang Bian and Xuewen Cao:

– Article: SuperSonic Gas Technologies; by: Jiang Bian and Xuewen Cao:Vladimir Feygin, Salavat Imayev, Vadim Alfyorov, Lev Bagirov, Leonard Dmitriev, John Lacey, TransLang Technologies Ltd., Calgary, Canada