3S Separator Technology — A Supersonic Shift in Gas Conditioning

Supersonic Gas Separation

The 3S (Supersonic Separation) separator is a compact, no-moving-parts device that uses controlled expansion, swirl, and pressure recovery to condense and remove water, heavy hydrocarbons, and acid gases — while preserving valuable line pressure. This article renders key content and data from an on-site (research) technical project and integrates insights from recent 3S-MOST publications.

Why Supersonic Separation?

Conventional gas-conditioning methods (Joule–Thomson valves, turbo-expanders, refrigeration, solvent systems) each trade simplicity, efficiency, footprint, and maintenance. The 3S approach harnesses the thermodynamics of rapid expansion and the fluid mechanics of high-intensity swirl to do three things at once: cool the gas, condense target species, and separate droplets — all inside a static device.

Design & Working Principle of the 3S Separator

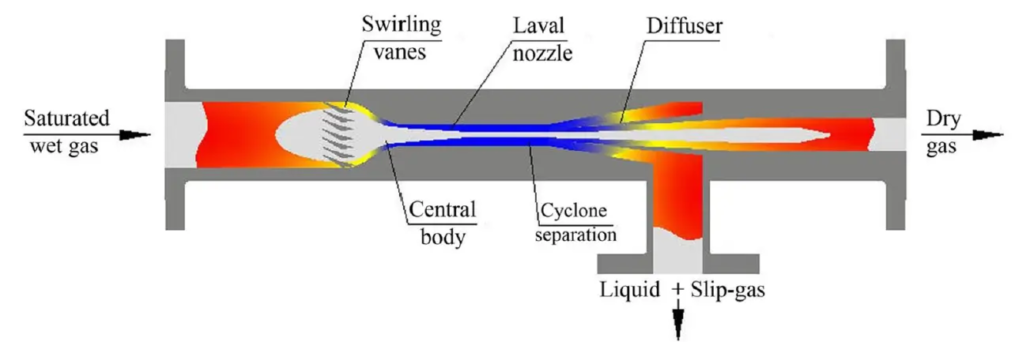

Feed gas receives angular momentum from a swirling part (swirling vanes). Entering a convergent–divergent (Laval) nozzle, the gas accelerates to supersonic speed. The rapid drop in static temperature creates supersaturation, nucleation, and droplet growth. Centrifugal forces drive droplets to the wall; the diffuser recovers part of the pressure while a liquid slip stream is routed to a downstream separator and dry gas continues to the consumer. 3s-most.eu

- Mach number: tuned so “target” components (water, C₂⁺, CO₂/H₂S) pass into liquid phase.

- Swirl intensity: balances efficiency with pressure drop and stability.

- Pressure recovery: diffuser restores part of lost pressure — outperforming simple throttles.

Process Flow Schemes

3S modules are strategically integrated upstream of cold boxes or Joule–Thomson (J-T) stages to pre-condense and remove heavy hydrocarbons, water, and other condensables before deep chilling. This lightens the thermal load on downstream refrigeration systems, reduces recycle gas volume, and improves overall process stability.

In more advanced process schemes, hybrid layouts combine 3S separators with turbo-expanders, creating a synergistic effect: the supersonic stage handles bulk condensation at minimal energy cost, while the expander polishes the stream to achieve ultra-low hydrocarbon dew points (HCDP) and enhanced NGL recovery. This configuration not only debottlenecks existing trains, but also simplifies process complexity, enabling smaller, more modular gas-conditioning units.

On-Site Technical Research: Data Comparison and Key Findings

Table 1. Comparative Characteristics of LTS Block — Field (1)

| Parameter | With 3S Separator | Without 3S Separator |

|---|---|---|

| Pressure in primary separator (MPa abs) | 12.0 | 12.0 |

| Gas temperature at heat-exchanger inlet (°C) | 7 | 7 |

| Pressure at 3S-block outlet (MPa abs) | 7.6 | 7.6 |

| Gas flow at separator 10C-1 outlet (m³/h) | 10,300 | 10,300 |

| Hydrocarbon dew point at outlet (°C, 75 atm) | Below −40 | −21.4 |

| Water dew point at outlet (°C, 75 atm) | Below −25 | −25.2 |

| Gas pressure at outlet (MPa abs) | 7.5 | 7.5 |

| C₅⁺ components in sales gas (g/m³) | < 4 | 8 |

| Droplet liquid in sales gas (g/m³) | Absent | 1.5 |

Table 2. Comparative Characteristics of LTS Block — Field (2)

| Parameter | With 3S Separator | Without 3S Separator |

|---|---|---|

| Pressure in primary separator (MPa abs) | 10.0 | 10.0 |

| Gas temperature at heat-exchanger inlet (°C) | 7 | 7 |

| Pressure at 3S-block outlet (MPa abs) | 7.6 | 7.6 |

| Gas flow at separator 10C-1 outlet (m³/h) | 10,300 | 10,300 |

| Hydrocarbon dew point at outlet (°C, 75 atm) | Below −30 | −15 |

| Water dew point at outlet (°C, 75 atm) | Below −25 | −25 |

| Gas pressure at outlet (MPa abs) | 6.6 | 6.6 |

| C₅⁺ components in sales gas (g/m³) | < 4 | 9 |

| Droplet liquid in sales gas (g/m³) | 0.6 | 1.3 |

Source: Adapted from a technical article ‘Low temperature 3S separator’, 2020 — by 3S-MOST for publication on www.3s-most.eu

Key Benefits of 3S Technology

- Static design: No moving parts — low maintenance, high reliability.

- Compact footprint: Ideal for offshore, FPSO, modular or brownfield retrofits.

- Pressure-smart: Recovers part of expansion loss; more efficient than pure throttling.

- Energy savings: Cuts refrigeration load and compressor power.

- Extended field life: Reduces backpressure; delays compressor installations.

Applications

Plant Debottlenecking

Integrate a 3S stage upstream of JT or cold-box units to reduce refrigeration demand and reach tighter dew point specs — boosting throughput and efficiency.

Hybrid with JT & Turbo-Expanders

Combining 3S with existing expanders merges their strengths: throttling simplicity with expander-like cooling depth.

Inlet Air Cooling for Turbines

Adapted 3S designs can remove moisture from intake air, increasing gas turbine performance (and potentially preventing icing or corrosion).

Design Considerations

- Mach number and nozzle geometry must match gas composition.

- Swirl intensity and diffuser design affect efficiency and recovery.

- CFD-aided optimization of nozzle shocks and boundary layers is critical for off-design stability.

- Residence time is milliseconds; nucleation and droplet growth must occur within the nozzle–diffuser length.

- Pressure budget planning is essential to maintain delivery specs.

Conclusion

The 3S Separator introduces a new era in gas conditioning: compact, reliable, and pressure-efficient. Data from the technical paper and on-site project confirms measurable improvements in compressor power, refrigerant use, and hydrocarbon dew point. Coupled with 3S’s latest designs, it stands as a next-generation technology for both onshore and offshore gas projects.