Modular NGL Recovery & Gas Conditioning / Enrichment for Smarter Midstream Operations

In today’s upstream and midstream gas landscape, operators face increasing pressure to monetize every hydrocarbon, reduce emissions, and keep CAPEX and OPEX under control. 3S Technology delivers a modular approach to NGL recovery, gas conditioning, and enrichment, combining advanced separation principles with plug-and-play scalability for fast, low-maintenance deployment.

Why NGL Recovery Matters

Recovering natural gas liquids (NGLs) such as ethane, propane, butanes, and heavier hydrocarbons has become a key profitability lever for gas producers. NGL extraction not only enhances product value but also contributes to emission reduction and resource optimization.

A recent technical review highlights that efficient NGL recovery is essential for both economic and environmental performance across the gas value chain (An Overview of Natural Gas Liquids Recovery and Fractionation Processes – 2023).

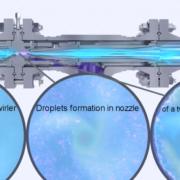

Further research demonstrates that replacing traditional Joule–Thomson valves with supersonic separators can significantly improve NGL recovery, underscoring the impact of modern compact systems (Nature Scientific Reports – 2022).

Key Takeaways

- NGL recovery adds significant margin beyond methane sales.

- Recovery efficiency directly impacts downstream fuel and power yields.

- Modular plants enable deployment in satellite or flare-gas recovery settings.

- Supersonic and modular systems can outperform traditional expansion methods in flexibility and uptime.

Keywords: NGL recovery, C3+ extraction, supersonic separator, modular skid, midstream optimization, natural gas liquids, flare gas monetization, process intensification

Gas Conditioning & Enrichment

Conditioning and enrichment ensure gas streams meet pipeline and process specifications — controlling hydrocarbon dew point, removing water, and enriching targeted components like C₂/C₃ to maximize plant throughput.

Academic work underscores the value of combining dew-point control, NGL removal, and enrichment to manage feed variability and boost recovery efficiency (Natural Gas Quality Enhancement: A Review of Conventional and Novel Treatment Technologies – 2016).

Professional studies from Siemens Energy demonstrate how modular fuel-gas conditioning systems reduce project schedules, simplify logistics, and improve lifecycle economics (Fuel Gas Conditioning System Modularization and Optimization – 2019).

Applications

- Pre-pipeline gas conditioning (dew-point and NGL removal)

- Gas enrichment to relieve cryogenic or fractionation bottlenecks

- Brownfield and satellite fields where full cryogenic units are uneconomic

- Capacity boost at existing GPPs or LNG feed conditioning

Keywords: gas conditioning, dew point control, enrichment module, C2/C3 recovery, pipeline specification, modular gas treatment, midstream skid installation

Why a Modular Approach Makes the Difference

Compared to conventional turboexpanders or chillers, modular systems like 3S Technology deliver:

- Shorter project timelines (often measured in months rather than years)

- Lower CAPEX and OPEX (compact designs, fewer moving parts)

- High flow tolerance (±15% per unit; scale by adding/removing parallel units)

- Minimal downtime (streamlined maintenance)

- Attractive payback (driven by liquids uplift and emissions reduction)

These traits align with current best practices for process intensification and distributed gas recovery (overview of NGL recovery and fractionation processes).

3S-MOST Applications

- Associated & flare-gas recovery — monetize waste streams while reducing emissions.

- Satellite or stranded fields — deploy compact skids without extensive civil works.

- Plant debottlenecking — use enrichment to raise throughput on existing assets.

- Peak-load balancing — scale modularly with flow changes.

External References (Technical)

- An Overview of Natural Gas Liquids Recovery and Fractionation Processes – 2023

- A Novel Strategy for Process Optimization of a Natural Gas Liquid Recovery Unit (supersonic separator) – 2022

- Fuel Gas Conditioning System Modularization and Optimization – Siemens Energy, 2019

- Natural Gas Quality Enhancement: A Review of Conventional and Novel Treatment Technologies – 2016

Ready to Transform Your Gas Stream into Value?

Share your latest gas analysis (composition, pressure, flow ± variability) and your processing goals. We’ll return a 3S Technology tailored block flow diagram, footprint, and payback snapshot for your site.