Supersonic Gas Separation – The Next-Generation Solution for Natural Gas Processing

In today’s energy market, the demand for efficient, compact, and environmentally friendly gas-treatment technologies has never been higher. Traditional separation methods—based on absorption, adsorption, or cryogenic expansion—often require large equipment, chemicals, and high energy consumption.

The supersonic separator, also called a supersonic gas separator, is a breakthrough solution that changes this paradigm.

By combining the principles of supersonic expansion, rapid cooling, and centrifugal separation, this technology enables dehydration, hydrocarbon dew-point control, acid-gas removal, and NGL recovery in a single compact unit.

Among all current solutions, the 3S supersonic gas separator has emerged as one of the most advanced and widely commercialized systems.

At M-ost Ltd (3S-MOST), we are the official licensee and global manufacturer of 3S technology, providing complete turnkey solutions for NGL recovery, gas conditioning, and CO₂/H₂S extraction to customers worldwide.

🔬 Scientific Basis of Supersonic Gas Separation

1️⃣ Supersonic Expansion and Non-Equilibrium Condensation

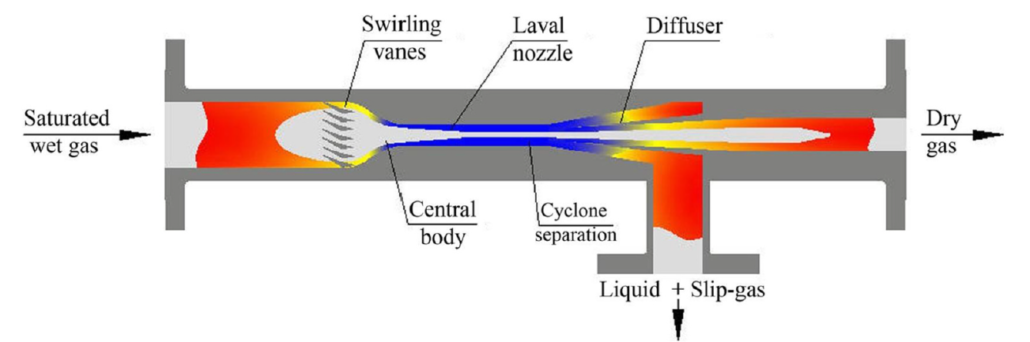

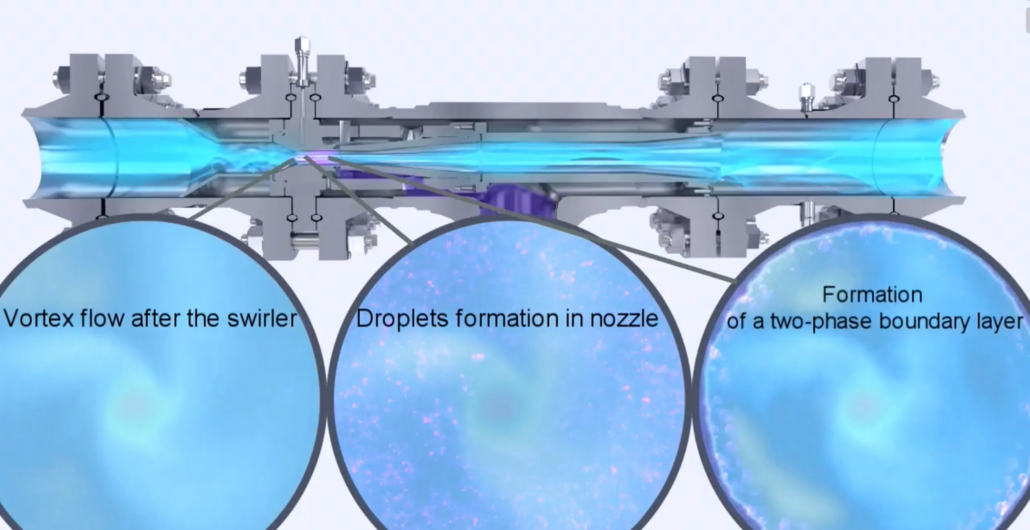

The core principle behind a supersonic separator is the rapid expansion of gas through a Laval (converging–diverging) nozzle.

As the gas accelerates to supersonic velocity, static pressure and temperature drop dramatically—sometimes to as low as −50 °C or below.

This sudden cooling induces non-equilibrium condensation of vapors such as water, CO₂, H₂S, and heavy hydrocarbons into fine liquid droplets.

This process happens within milliseconds, making it much faster than conventional chilling or absorption systems. It also avoids hydrate formation due to the extremely short residence time of the gas in the separator.

2️⃣ Swirl Flow and Centrifugal Separation

To separate the condensed droplets from the gas, a swirler or vortex generator imparts a strong rotational motion to the flow.

This creates powerful centrifugal forces—thousands of times greater than gravity—which drive condensed droplets outward toward the walls.

The purified gas moves through the centerline, while the liquid phase is extracted through dedicated drainage ports.

3️⃣ Energy Efficiency and Compact Design

A diffuser section downstream of the separation zone recovers some of the lost pressure energy, increasing overall efficiency.

Because the system uses the gas’s own expansion energy—not external refrigeration or chemicals—it operates with very low power consumption.

This results in a compact, efficient, and low-maintenance solution ideal for both onshore and offshore gas-processing facilities.

⚙️ Components of a Supersonic Separator

- Laval Nozzle – accelerates gas to supersonic velocity

- Swirler (Vortex Generator) – induces strong centrifugal forces

- Separation Section – condensation and liquid separation zone

- Diffuser – recovers pressure and stabilizes outlet flow

- Liquid Collection System – removes condensed phases efficiently

Together, these components perform the entire process—cooling, condensation, and separation—within a single, compact device.

🌍 Key Advantages of Supersonic Separation

✅ Compact and lightweight: Perfect for space-limited sites, including offshore platforms and skid-mounted applications.

✅ Chemical-free operation: No glycol, amine, or other chemicals needed for dehydration or acid-gas removal.

✅ Multi-functional process: Performs dehydration, NGL recovery, and CO₂/H₂S extraction in one unit.

✅ High reliability: No moving parts, minimal maintenance, and simple control.

✅ Fast response: The process is nearly instantaneous; no large inventories of gas or liquid.

✅ Environmentally friendly: Eliminates chemical waste and reduces greenhouse gas emissions.

✅ Cost-effective: Reduced CAPEX and OPEX compared to conventional technologies.

🧠 The 3S Supersonic Gas Separator – Patented & Proven

The 3S supersonic gas separator is a patented technology, recognized for its unique design and performance.

It is protected under international patent filings, including:

- US8696793 – Supersonic Gas Separator (PDF link)

- CN101828088B – Supersonic Separation Device and Method (PDF link)

These patents cover the fundamental design and operation of the 3S supersonic separator, ensuring global protection and consistent quality.

At M-ost Ltd (3S-MOST), we are the official licensee and worldwide manufacturer of this patented technology.

Every 3S unit is custom-engineered to the client’s feed-gas composition, pressure, temperature, and target separation efficiency.

🏭 Industrial Applications

The 3S supersonic gas separator is versatile and applicable to a broad range of industrial gas processes:

🔹 Gas Conditioning & Enrichment

- Removes water vapor and heavy hydrocarbons (C₂+, C₃+)

- Controls gas dew-point to prevent hydrate formation

- Improves pipeline gas quality and heating value

🔹 NGL Recovery

- Extracts propane, butane, and heavier hydrocarbons (C₃+ fractions)

- Reduces the need for bulky cryogenic systems

- Ideal for onshore plants and offshore platforms

🔹 CO₂ / H₂S / Acid Gas Separation

- Partially or completely removes acid gases from raw natural gas

- Can operate standalone or as a pre-treatment before amine/membrane systems

- Enables cleaner, specification-grade natural gas

🔹 LNG & Cryogenic Pre-Treatment

- Reduces CO₂ and heavy hydrocarbon content before liquefaction

- Improves LNG yield and plant efficiency

- Integrates seamlessly into existing LNG pre-treatment trains

🔹 Offshore & Subsea Gas Processing

- Compact, lightweight, and low-maintenance

- Suitable for unmanned or subsea installations

- Reduces space, weight, and operational risk

🧩 Why Choose 3S-MOST

- Official 3S licensee and global manufacturer

- Tailored engineering for specific gas compositions and process goals

- Compact, modular units ready for plug-and-play installation

- Proven track record in industrial and offshore environments

- Global delivery, commissioning, and after-sales support

- Dedicated inquiry forms for quick and accurate proposals

🟢 Inquiry Forms:

- 3S Separator General Inquiry

- Gas Dew-pointing Inquiry

- CO₂ Separation / Extraction Inquiry

- C₂+, C₃+ Extraction Inquiry

🌐 The Future of Gas Processing is Supersonic

Supersonic gas separation combines advanced fluid dynamics with industrial practicality.

It offers an environmentally responsible and energy-efficient way to treat natural gas while meeting modern operational demands.

The 3S supersonic gas separator, developed under international patents and commercialized globally by M-ost Ltd (3S-MOST), represents the next generation of separation technology—delivering superior performance, low maintenance, and compact design.

⚡ Get in Touch

Are you ready to bring supersonic efficiency to your gas processing operations?

Contact us today to discuss your project or request a customized 3S supersonic separator proposal.

🔗 Request a 3S Separator Proposal

✅ M-ost Ltd (3S-MOST) — official licensee, manufacturer, and global supplier of the 3S supersonic gas separator technology.

Compact. Efficient. Chemical-free. The future of gas processing is supersonic.