3S Technology offers groundbreaking solutions for gas separation by employing patented supersonic technology to achieve superior efficiency and sustainability in processing natural and associated gas. Fully developed in 1997 and rigorously field-tested, 3S Technology is protected by global patents in over 30 countries. This widespread recognition highlights its advanced engineering and relevance across diverse applications in the oil and gas industry.

The core of 3S Technology lies in its integration of supersonic flow dynamics. This approach enables precise gas separation while maintaining a compact, reliable, and environmentally friendly design. By combining simplicity with innovation, 3S Technology has emerged as a transformative force in modern gas processing, offering sustainable solutions that align with the industry’s evolving demands

Revolutionizing Gas Processing with 3S Supersonic Separation: Efficiency Meets Sustainability

3S Technology stands for Super-Sonic Separation, an innovative approach to gas processing that revolutionizes traditional methods. It uses the principles of supersonic flow to achieve efficient gas separation and conditioning. Developed as an advanced alternative to Joule-Thomson (JT) valves and turbo-expanders, this technology delivers a unique combination of simplicity, efficiency, and cost-effectiveness.

Unmatched Advantages and Transformative Power of 3S Technology

- Compact and Reliable Design: Supersonic separators have no moving parts, which drastically enhances reliability and reduces maintenance costs compared to traditional systems like compressors or turbo-expanders. This feature makes them especially suitable for remote and offshore installations where maintenance operations can be challenging.

- Energy Efficiency: By leveraging supersonic flow dynamics, the technology minimizes energy requirements, making it an environmentally friendly solution. It also helps conserve reservoir energy, which is particularly beneficial in energy-intensive applications such as offshore gas processing.

- Versatility: The 3S separators can handle various tasks, including:

- Gas dehydration

- Heavy hydrocarbon extraction

- CO2 and H2S removal

- Liquefied natural gas (LNG) production

- Dew point control for pipeline transportation

- Cost Savings: The compact design reduces both capital expenditures (CAPEX) and operational expenses (OPEX).

- High Separation Efficiency: Utilizing rapid cooling and cyclonic separation, 3S technology achieves superior efficiency in recovering heavier hydrocarbons and separating CO2. This is especially advantageous for applications requiring high levels of liquid recovery, such as in natural gas liquids (NGL) processing.

Game-Changing Applications of Supersonic Technology: Unlock CAPEX Savings of Up to 40%!

Super Sonic technology is widely used in challenging environments, including offshore platforms, subsea installations, and regions with high CO2 or heavy hydrocarbon content in gas fields. Its ability to adapt to both high- and low-pressure conditions ensures its utility across diverse settings.

│ Advantages of Supersonic Separators

Most Ltd, an organization focused on fostering global partnerships, promotes a collaborative approach to business.

Collaborating with major global players, 3S Technology has established itself as a pioneer in the oil and gas industry. Through strategic partnerships and regional expertise, the company delivers bespoke solutions tailored to diverse industrial needs.

Mastery in Deployment and Regional Expertise

M-ost Ltd., an official licensee of 3S Technology, manages its deployment across several countries, including Argentina, Brazil, and EU regions. The company ensures seamless project execution, from manufacturing and shipping to installation and commissioning. Customized solutions and local support further enhance the technology’s accessibility for varied industrial needs.

By combining energy efficiency, reduced environmental impact, and operational simplicity, Super Sonic Technology is shaping the future of gas processing, offering an optimal solution for industries aiming to enhance sustainability and economic viability.

│ Advantages of Supersonic Separators

│ Numerical analysis – Low Temperature Separation

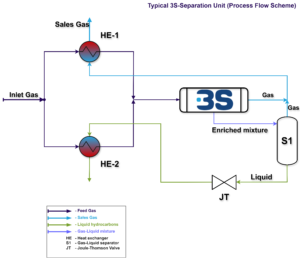

│ Standard Process Flow Scheme for 3S-Separation Units

By integrating patented supersonic technology with an eco-friendly, compact design, 3S Technology continues to redefine gas processing. Its commitment to energy efficiency, environmental sustainability, and operational simplicity positions it as a transformative force in the energy sector.

Moreover, we support our customers with end-to-end services, from process flow design to installation and commissioning. This comprehensive approach ensures that clients receive systems tailored to their specific requirements, backed by robust project management and global operational support.

In conclusion, 3S Technology’s innovative supersonic separation solutions are transforming the gas processing industry with their unmatched efficiency, sustainability, and cost-effectiveness. By leveraging advanced aerodynamic principles, 3S separators offer significant energy savings, enhanced reliability, and reduced operational costs.

This technology is setting new standards for gas treatment, providing businesses with a reliable, eco-friendly, and economically viable solution. Embracing 3S Technology promises a future of optimized gas separation with lasting environmental and economic benefits.