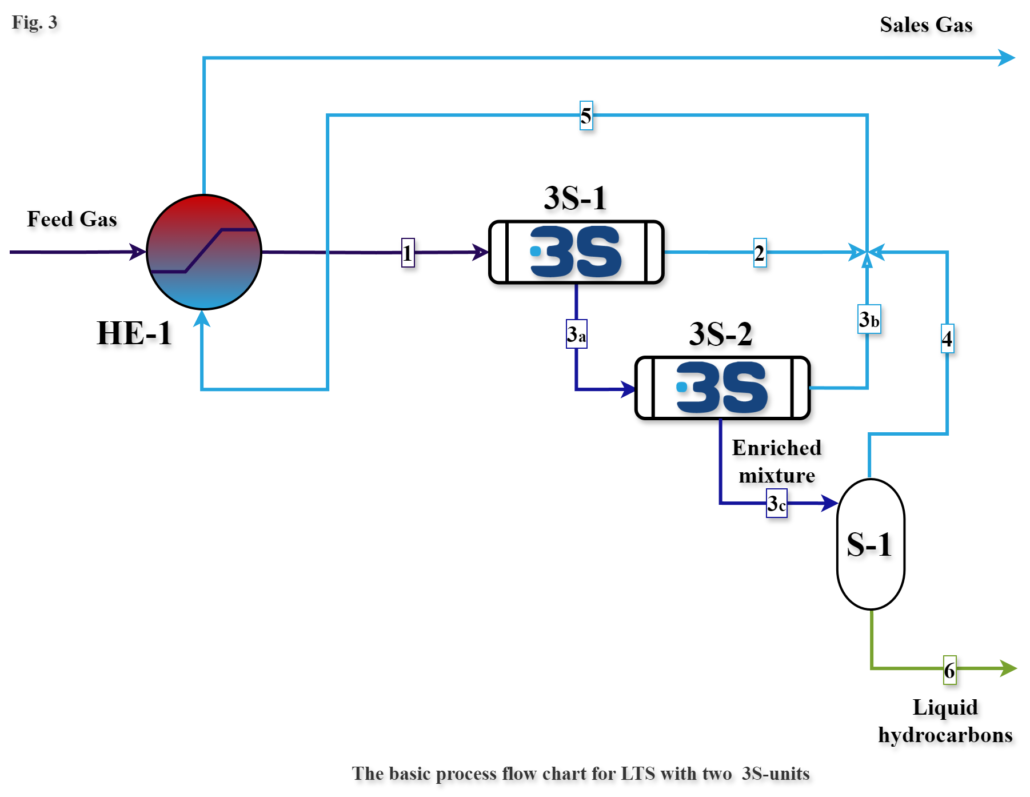

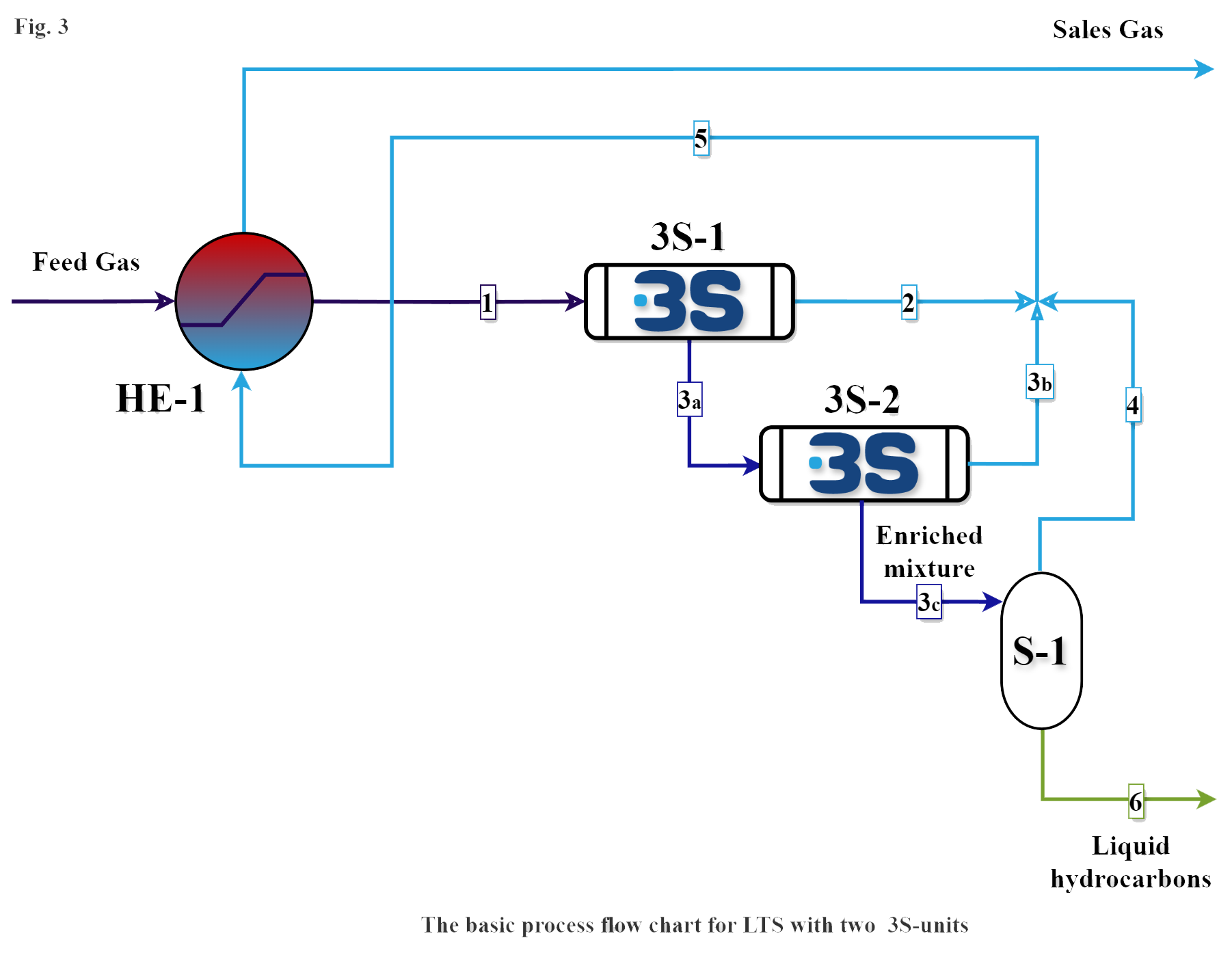

LTS unit with two 3S-separators (LTS – 2 x 3S)

- (Fig. 3.) – Explanation based on simplified process flow chart

The natural gas flow feeds into the heat exchanger HE-1, whereat the gas is refrigerated by the conditioned outlet gas flow. The gas flow [1] from the outlet of the heat exchanger is directed to the inlet of the 3S-separator (3S-1), whereat the flow is swirled and refrigerated in the Laval nozzle, with the subsequent water and condensate droplets formation and coagulation, and further drift of the droplets towards the boundary layer and separation into two flows: the purified from water and condensate flow [2] and the enriched with water and condensate flow [3a].

In the traditional LTS projects the most common flow ratio of flows [2] and [3a] is 70% by 30%. In order to maintain the supersonic mode of the 3S-separator operation the pressure drop has to be above 26% and it’s determined by the requirements to the dew point temperatures.

The flow [3a] enters into the special 3S-separator (3S-2), which operates in subsonic mode with a minimum pressure drop (approximately 0.5 bar). High quality separation of the flow [3a] takes place in this 3S-separator where it splits into gas-liquids flow [3c] (with small gas content) and pure gas flow [3b].

The ratio of the flows [3b] and [3c] is 80% by 20%. The liquid phase in the flow [3c] is separated from the gas in the traditional gas-liquid separator S-1.

The gas flow[5] passes through the heat exchanger HE-1, where it is heated, and then directed into the sales gas pipeline for further transportation. The unstable liquid flow [6] is directed into the stabilization column.