Supersonic Separators: Merging the Best of Joule-Thomson Valves and Turbo-Expanders

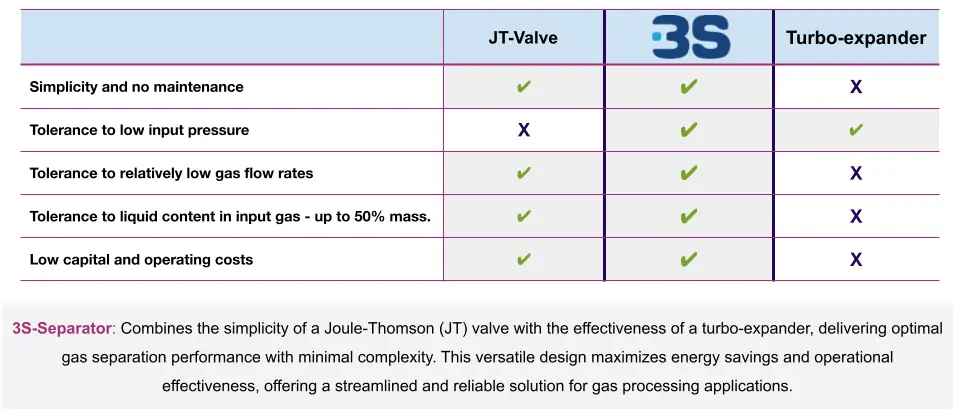

In the world of natural gas processing, technologies such as Joule-Thomson (JT) valves and turbo-expanders have long been employed to reduce the temperature of gases, separate gas components, and recover valuable by-products. These systems, though effective, often come with trade-offs between efficiency, complexity, and cost. However, the advent of Supersonic Separators, such as the 3S-Separator, represents a transformative step in gas processing, merging the simplicity of JT valves with the efficiency of turbo-expanders to offer a highly effective and energy-efficient solution for gas separation.

This article explores how supersonic separators combine the core functionalities of JT valves and turbo-expanders, explains their technical properties, and highlights their advantages in various gas processing applications.

Joule-Thomson (JT) Valves: Simple, but Limited

JT valves operate on the principle of the Joule-Thomson effect, which describes the temperature change in a gas as it expands through a valve without exchanging heat with its surroundings. In a gas processing plant, JT valves are typically used for:

- Pressure Reduction: Gas pressure is reduced by allowing it to expand through the valve.

- Temperature Drop: Due to the Joule-Thomson effect, the temperature of the gas decreases during the expansion.

- Condensation: This cooling effect helps in condensing heavier hydrocarbons, such as natural gas liquids (NGL), enabling their separation from the gas stream.

Advantages of JT Valves:

- Simplicity: The JT valve is a passive device with no moving parts, making it easy to maintain and operate.

- Cost-Effective: JT valves are relatively inexpensive compared to more complex systems.

- Low Energy Requirements: The process is passive and doesn’t require additional energy input.

Limitations of JT Valves:

- Limited Efficiency: The cooling efficiency is relatively low, and the process can result in suboptimal recovery of hydrocarbons.

- Pressure Dependency: JT valves require a significant pressure differential to induce meaningful cooling.

- Fixed Output: The degree of cooling cannot be easily controlled or optimized.

Turbo-Expanders: Efficient, but Complex

Turbo-expanders operate by expanding high-pressure gas through a turbine, which generates mechanical energy as the gas does work on the turbine blades. The mechanical energy can be used to drive compressors or generate electricity, and the gas exiting the expander experiences a significant temperature drop, making it ideal for gas separation.

Key Functionalities of Turbo-Expanders:

- Pressure Reduction: Like JT valves, turbo-expanders reduce the pressure of the gas.

- Efficient Cooling: Turbo-expanders achieve a much greater temperature drop than JT valves, leading to enhanced separation of NGLs and other components.

- Energy Recovery: The mechanical energy produced by the turbine can be harnessed for other processes, improving overall energy efficiency.

Advantages of Turbo-Expanders:

- High Efficiency: Turbo-expanders provide significantly better cooling and separation efficiency than JT valves.

- Energy Recovery: The ability to convert mechanical energy into usable power or drive compressors makes turbo-expanders energy efficient.

- Precision Control: Turbo-expanders allow for more precise control over the cooling process.

Limitations of Turbo-Expanders:

- Complexity: Turbo-expanders are complex mechanical systems with moving parts, making them more prone to wear and requiring higher maintenance.

- Higher Costs: The initial investment and operational costs are higher due to the complexity of the system.

- Energy Requirements: While turbo-expanders recover energy, they often require higher energy inputs than simpler systems like JT valves.

Supersonic Separators: The Best of Both Worlds

Supersonic separators, such as the 3S-Separator, combine the simplicity of JT valves with the high efficiency of turbo-expanders. These separators work by forcing gas into a supersonic flow regime, creating a pressure drop and rapid cooling effect that facilitates gas separation. The process mimics key properties of both JT valves and turbo-expanders but offers unique advantages that improve overall gas processing performance.

Core Functionalities of Supersonic Separators:

- Supersonic Flow and Cooling: Gas is accelerated to supersonic speeds in a Laval nozzle (a converging-diverging nozzle), causing an adiabatic expansion that results in a significant pressure drop and a rapid cooling effect. This mirrors the cooling efficiency of turbo-expanders but with a much simpler design.

- Gas-Liquid Separation: The rapid cooling causes heavier hydrocarbons (such as NGLs) and water vapor to condense into liquid form, which can then be separated from the gas stream.

- Cyclonic Action: After the supersonic expansion, the gas undergoes a cyclonic effect, which separates the liquid and solid particles from the gas due to centrifugal forces. This separation is more efficient than the conventional gravity-based separation seen in JT systems.

- No Moving Parts: Like JT valves, supersonic separators have no moving parts, making them robust, reliable, and low-maintenance.

- Energy Efficiency: Supersonic separators operate passively, requiring little to no external energy input, while achieving comparable cooling and separation results to turbo-expanders.

Properties and Characteristics of Supersonic Separators:

- Pressure Reduction and Cooling: Similar to both JT valves and turbo-expanders, supersonic separators achieve a large pressure drop and rapid cooling. However, they do this more efficiently by leveraging supersonic flows rather than relying solely on expansion through a valve or turbine.

- High Efficiency: The efficiency of separation in supersonic separators rivals that of turbo-expanders, particularly in recovering NGLs and other valuable by-products.

- Compact and Simple Design: While turbo-expanders are large and complex, supersonic separators offer a compact, simple design that is easier to install and operate.

- Cost-Effective: The simplicity of the design reduces both CAPEX and OPEX. Maintenance costs are lower due to the absence of moving parts, and the initial cost is generally less than a full turbo-expander system.

- Energy Recovery Potential: While supersonic separators don’t generate mechanical energy like turbo-expanders, the energy efficiency gained through their passive operation offsets this, making them an ideal choice for energy-conscious operations.

Supersonic Separators in Application: Key Benefits

NGL Recovery:

In gas plants, supersonic separators are particularly valuable for NGL recovery, as they achieve high levels of liquid extraction without the complexity of turbo-expanders. The supersonic expansion leads to a sharp temperature drop, causing heavy hydrocarbons to condense and separate from the gas stream efficiently.

CO2 and Water Removal:

Supersonic separators are also used for CO2 and water vapor removal, addressing challenges in gas fields with high CO2 content. The rapid cooling provided by the supersonic flow causes CO2 to condense and be removed as a liquid, significantly reducing its concentration in the gas stream.

Dew Point Control:

For pipeline transportation, dew point control is critical to avoid condensation issues. Supersonic separators offer a reliable solution by achieving effective gas cooling, ensuring that heavier hydrocarbons are removed and the gas remains in a stable phase during transit.

Conclusion

Supersonic separators like the 3S-Separator offer a revolutionary combination of the simplicity of JT valves and the efficiency of turbo-expanders, without the downsides of complexity or high energy consumption. By utilizing supersonic flow dynamics, these separators achieve rapid pressure drop and cooling, enabling efficient gas separation with minimal operational costs. Their compact, energy-efficient design makes them an ideal solution for a variety of applications in natural gas processing, from NGL recovery to CO2 removal and dew point control. This technology represents a significant leap forward in gas processing, offering a reliable and cost-effective alternative to traditional systems.