Inlet Air Cooling for Gas Turbine using 3S-Separator

The Need for Inlet Air Cooling in Gas Turbine Power Plants in Hot and Humid Environments, and the Application of 3S Separators

Gas turbine power plants are widely used for electricity generation due to their efficiency and reliability. However, they are highly sensitive to ambient conditions, particularly temperature and humidity. In hot and humid environments, gas turbines face significant operational challenges, especially because hot air is less dense, reducing the power output and increasing the compressor work required. This leads to a decrease in efficiency, especially when ambient temperatures exceed 40°C. (The effects are particularly pronounced in hot regions, where ambient temperatures can exceed 40°C, leading to power output reductions of up to 30%.) Therefore, cooling the air before it enters the turbine’s compressor is critical for improving performance in these conditions.

Challenges in Hot and Humid Environments

- High Temperatures: In hot climates, such as deserts or tropical regions, the reduced air density decreases oxygen content for combustion, leading to reduced turbine output and increased energy consumption by the compressor. Power output can drop by up to 30% in these conditions.

- Humidity: In tropical regions or areas with high humidity, the presence of water vapor reduces combustion efficiency, as the water vapor displaces oxygen in the air.

Traditional Inlet Air Cooling Solutions

Several cooling methods are commonly used to address these challenges:

- Evaporative Cooling: Cools the inlet air by evaporating water, which works well in dry climates but is less effective in humid environments.

- Chiller Systems: Use mechanical refrigeration to cool the air but are energy-intensive and costly.

- Fogging Systems: Spray water droplets into the intake air, cooling it as the water evaporates. This method is cost-effective but less efficient in very humid conditions.

- Thermal Energy Storage (TES): Uses chilled water or ice stored during off-peak hours to cool the air during peak demand, but requires significant infrastructure investment.

The 3S Separator as a Cooling Solution

An innovative and highly efficient approach to cooling inlet air for gas turbines is the 3S (Supersonic Swirling Separator) technology. Originally developed for the oil and gas sector to separate gas mixtures, the 3S separator operates by accelerating gases through a convergent-divergent Laval nozzle, causing rapid cooling and condensation of gas-phase components. The cooling effect generated by this process makes it an ideal candidate for use in gas turbine inlet air cooling.

Application of 3S Separators for Inlet Air Cooling

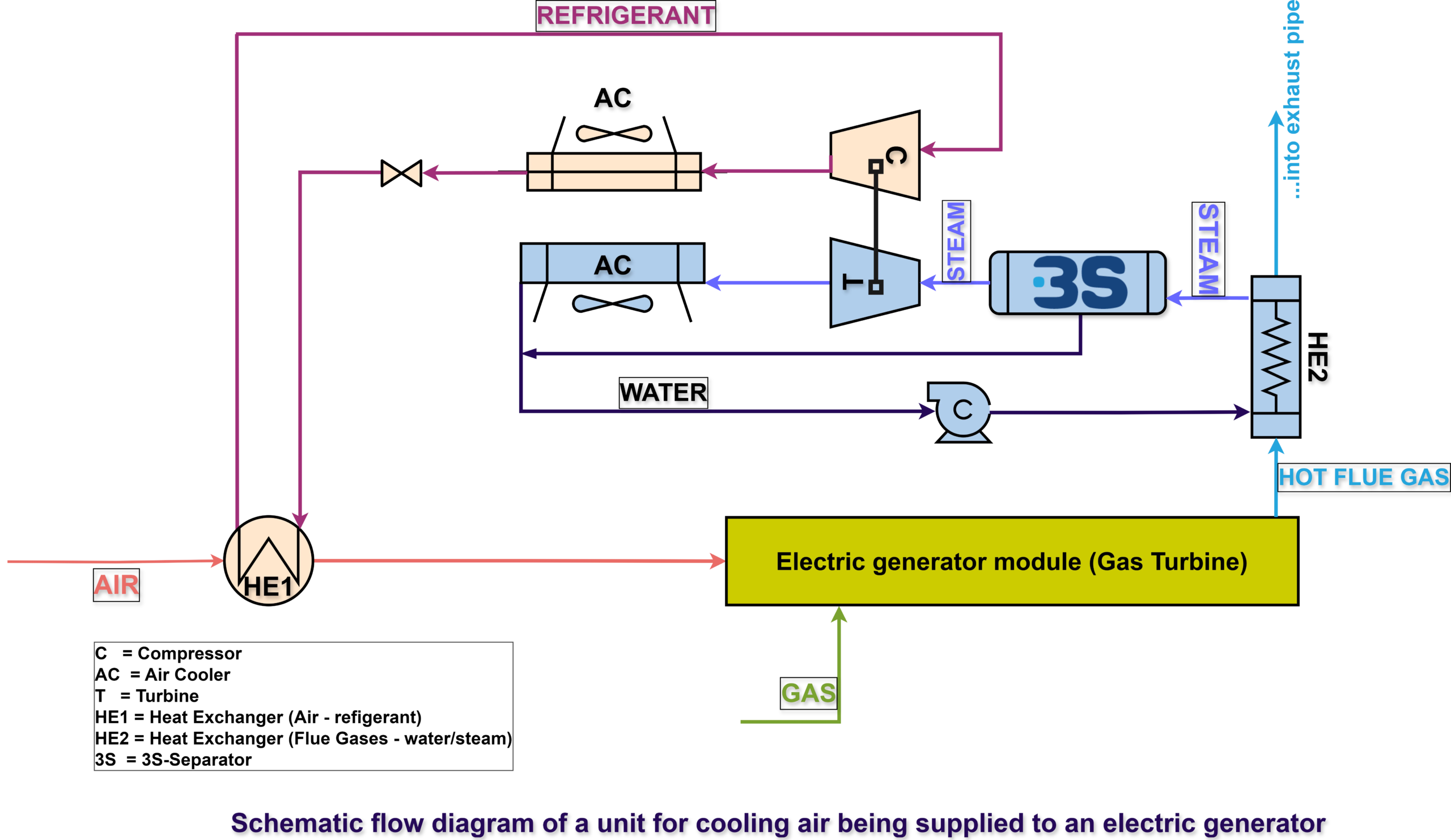

In this application, the 3S separator can be integrated into a cooling system that uses free energy from various sources to power a refrigeration cycle. The proposed system utilizes hot flue gases from the turbine exhaust to generate the required cooling for the turbine’s inlet air.

Proposed 3S Separator-Based Cooling System Using Hot Flue Gases

The system operates as follows:

- Heat Exchanger (HE2): Hot flue gases from the gas turbine heat water in a heat exchanger. The pressurized water is then transformed into a vapor-liquid mixture.

- 3S Separator: The vapor-liquid mixture enters the 3S separator, where the liquid phase is separated from the vapor. The supersonic swirling flow enhances the separation, allowing the vapor fraction to power a turbine connected to a compressor.

- Turbine (T) and Compressor (C): The turbine, driven by the vapor from the 3S separator, powers the compressor, which operates a refrigeration cycle (closed circuit) using a refrigerant such as freon or propane.

- Heat Exchanger (HE1): In this heat exchanger, the cooled refrigerant absorbs heat from the inlet air, reducing its temperature before it enters the gas turbine’s compressor.

- Water Recirculation: The separated water is recirculated to the pump (if applicable), ensuring continuous operation.

This configuration takes advantage of the waste heat generated by the turbine itself, thus reducing the need for external energy inputs and enhancing the overall efficiency of the cooling process.

Alternative Source: Free Energy from Pressure Drop in Gas Distribution Pipelines

Apart from utilizing the waste heat from hot flue gases, the 3S separator can also harness free energy from pressure drops in nearby gas distribution pipelines. In many cases, natural gas pipelines experience significant pressure reductions as gas is transported to lower-pressure distribution networks. This energy can be recovered and used to power the refrigeration system for cooling the gas turbine’s inlet air.

Advantages of 3S Separator-Based Cooling Systems

- Energy Efficiency: By using waste heat from flue gases or free energy from pressure drops, the 3S separator significantly reduces the need for external energy inputs, improving the overall energy efficiency of the cooling process.

- Environmentally Friendly: The system leverages renewable energy sources (waste heat or pipeline pressure drops), reducing the carbon footprint of the gas turbine plant.

- Cost-Effectiveness: The 3S separator-based system eliminates the need for large, energy-intensive chillers, offering a compact and cost-efficient solution.

- Flexibility: The system can be adapted to various refrigerants and environmental conditions, making it suitable for a wide range of climates and regulatory requirements.

Local Specificities for Application

- Desert and Arid Regions (e.g., Middle East, North Africa): In areas with high ambient temperatures, the 3S separator system can utilize the excess heat from flue gases to cool the turbine inlet air. The system’s ability to operate efficiently in high temperatures makes it ideal for these regions.

- Tropical and Humid Regions (e.g., Southeast Asia, Brazil): In hot and humid environments, the 3S separator can cool and dehumidify the air before it enters the turbine, improving performance in conditions where both temperature and humidity negatively impact gas turbine efficiency.

- Regions with Developed Gas Infrastructure (e.g., U.S., Europe): Where high-pressure gas distribution pipelines are available, the 3S separator can harness the free energy from pressure drops in the pipelines, providing an additional energy-efficient cooling option.

Conclusion

The 3S separator presents an innovative solution for cooling gas turbine inlet air in hot and humid environments. By utilizing free energy from either hot flue gases or pressure drops in nearby gas pipelines, the system offers a flexible, energy-efficient, and cost-effective alternative to traditional cooling methods. As gas turbines continue to play a critical role in global power generation, especially in regions with extreme temperatures, the adoption of 3S technology for inlet air cooling can help ensure more reliable and efficient power generation.