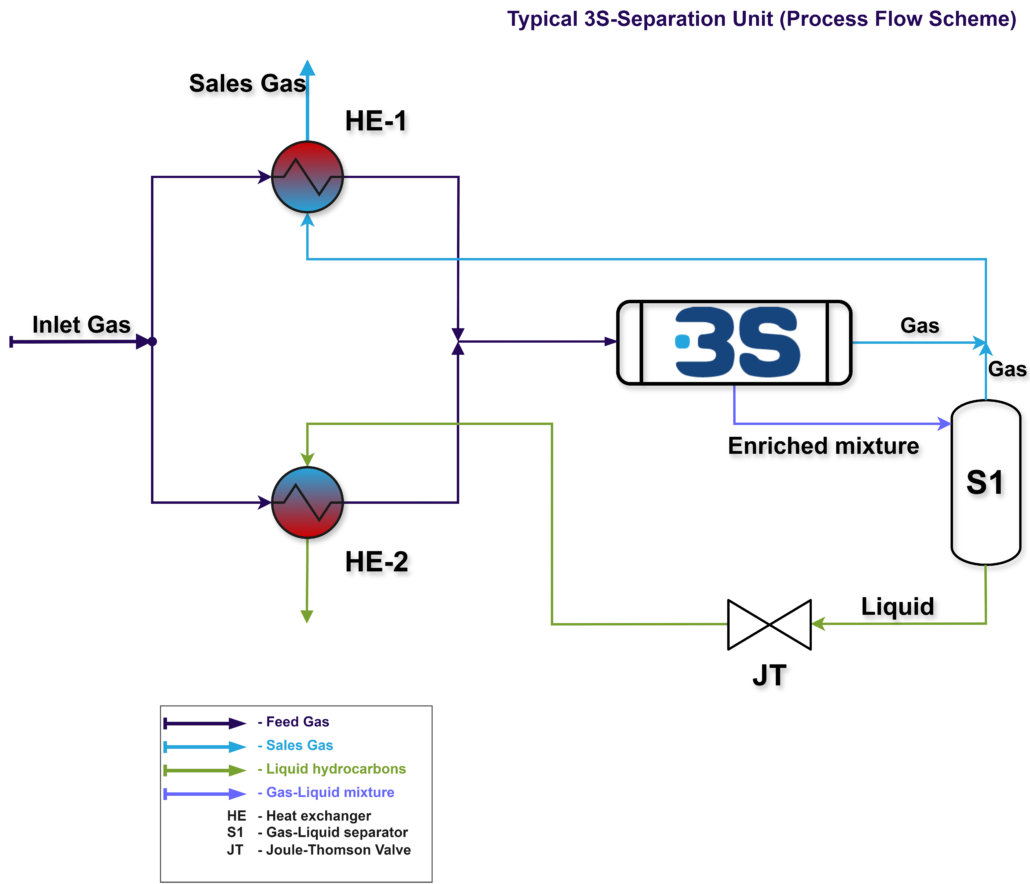

Process Flow Scheme – 3S Separator

The inlet gas is divided into two streams: one is cooled at the [HE-1] Heat Exchanger, and the other at the [HE-2] Heat Exchanger.

To achieve efficient liquid extraction in the [3S-separator], the inlet gas is chilled to approximately minus –70°C to minus –90°C.

The cooled gas streams are combined and sent to the [3S-separator], where they are split into two outputs: a treated gas stream and a rich gas-liquid stream (comprising 15-30% of the inlet gas volume). This rich stream is directed to the [S1] low-temperature separator.

Gas from the [S1] separator is mixed with treated gas from the [3S-separator] and sent to [HE-1], where it is reheated by the cooling inlet gas. This results in the final NGL plant sales gas, primarily consisting of methane with a small amount of ethane.

The unstable liquid from [S1] is throttled and sent to [HE-2], where it cools part of the inlet gas by partially evaporating (acting as an evaporator).

After passing through [HE-2], the rich gas-liquid mixture, or “ethane-enriched condensate,” is processed in a conventional low-temperature separation (LTS) unit.

Key benefits of this process include efficient heat recovery, enhanced liquid extraction, and optimized gas processing with minimal energy consumption.