3S Separator Technology: A Breakthrough in Supersonic Gas Separation

3S Separator Technology: A Breakthrough in Supersonic Gas Separation

Overview of the 3S Separator

The 3S Separator (SuperSonic Separation) is a revolutionary technology for natural gas and process gas treatment, offering an innovative, highly efficient, and compact solution for gas-liquid and gas-solid separation. Built upon the principle of supersonic expansion, the 3S Separator utilizes advanced fluid dynamics to create extreme thermodynamic conditions, achieving condensation and separation in a single, continuous, and energy-efficient process.

The 3S system offers a new paradigm in gas conditioning, dehydration, and hydrocarbon dew point control, enabling significant operational and economic advantages over conventional technologies such as Joule-Thomson (JT) valves, glycol dehydration, and mechanical separation.

How It Works: The Supersonic Separation Principle

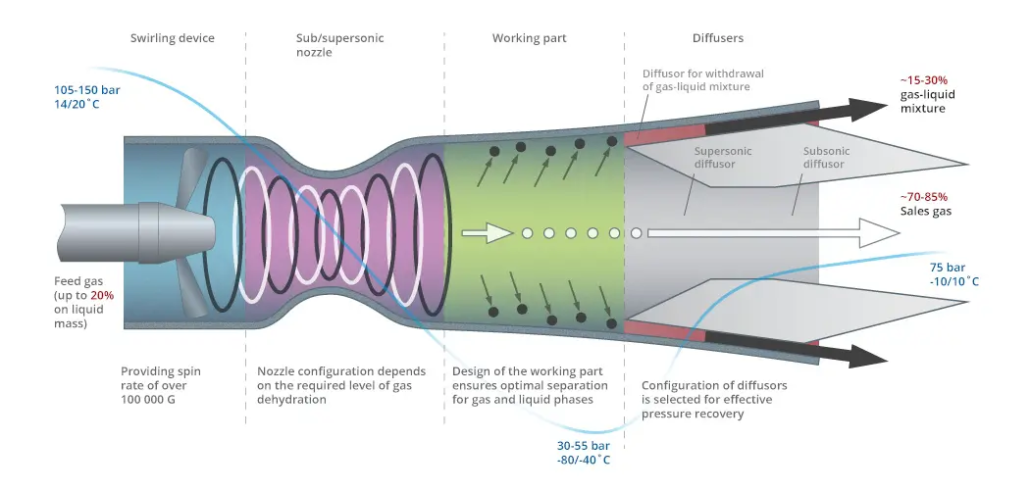

The 3S Separator operates through a multi-step process:

- Acceleration and Expansion: The gas enters a Laval nozzle where it is accelerated to supersonic speeds. This expansion causes a rapid drop in temperature and pressure.

- Condensation: Due to the extreme cooling, heavier hydrocarbons, water, and other condensable components form droplets.

- Swirling and Separation: A swirl element imparts a high centrifugal force, driving droplets and solid particles to the walls, separating them from the gas stream.

- Recompression and Recovery: The lean gas is recompressed, and the separated liquids and solids are extracted downstream.

This sequence occurs in a matter of milliseconds, without moving parts, resulting in highly reliable and low-maintenance operation.

🔗More => 3S separator operating principle

Key Features of the 3S Separator

| Feature | Description |

|---|---|

| No Moving Parts | Ensures high reliability and minimal maintenance. |

| Compact Design | Up to 70% smaller and lighter than traditional systems. |

| Energy Efficient | Utilizes pressure drop instead of external power for operation. |

| Modular and Scalable | Easily integrated into various system sizes and configurations. |

| Instantaneous Response | Separation occurs in milliseconds, enabling real-time process adjustments. |

Typical Applications

Common Uses

- Natural Gas Processing

- Pipeline Gas Conditioning

- Hydrocarbon Dew Point Control

- Gas Dehydration

- CO2 and H2S Removal (with upstream cooling and sorbents)

- NGL (Natural Gas Liquids) Recovery

Process Flow Example – 3S Separator

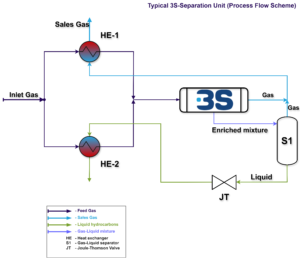

The following schematic outlines a typical 3S Separation Unit:

- Feed gas is pre-cooled (if needed).

- The gas passes through the Laval nozzle and swirling chamber.

- Condensates are removed via a cyclonic separation zone.

- Clean, dry, and conditioned gas exits the system.

This layout can be adapted for upstream, midstream, and downstream operations depending on the customer’s process requirements.

🔗More => Standard Process Flow Scheme 3S separator

Benefits of the 3S Technology

| Benefit | Impact |

|---|---|

| Enhanced Gas Quality | Delivers pipeline-spec or sales-grade gas without additional treatment. |

| Lower Operational Costs | No chemical reagents, heaters, or compressors needed downstream. |

| Increased Liquid Recovery | High efficiency in NGL and condensate separation. |

| Environmental Compliance | Reduced emissions and zero venting possible. |

| Fast ROI | Lower CAPEX and OPEX with short payback periods. |

| Minimal Footprint | Ideal for offshore platforms, FPSOs, and remote installations. |

Comparing Technologies

Technology Comparison

| Technology | 3S Separator | JT Valve | Glycol Dehydration | Mechanical Separator |

|---|---|---|---|---|

| Moving Parts | No | No | Yes | Yes |

| Footprint | Small | Medium | Large | Medium |

| Energy Requirement | Low | Medium | High | Medium |

| Separation Efficiency | High | Medium | High (dehydration) | Low |

| Liquid Recovery | High | Medium | Low | Low |

| Environmental Impact | Low | Medium | High (chemicals) | Medium |

Why Choose 3S Technology?

The 3S Separator is a proven and field-tested solution designed for modern energy systems. Whether your goal is to maximize liquid recovery, meet pipeline specs, reduce operating costs, or increase process efficiency, the 3S system provides a powerful alternative to legacy technologies.

With multiple units successfully operating in harsh environments and across diverse applications, the 3S solution is ready to meet the challenges of the evolving energy landscape.

More => 3S separator & 3S technology projects world wide

Contact and Integration Support

3S offers comprehensive engineering support, from feasibility studies to full integration into existing or new gas processing systems.

To learn more about how the 3S Separator can enhance your operations, contact our team or visit:

For more information on how the 3S Separator can improve your operations, get in touch with our team or visit:

🔗 www.3s-most.eu

🔗3S Separator – Inquiry Form