3S TECHNOLOGY

Link to: Get in touch

Any more questions? Feel free to write us a mail!

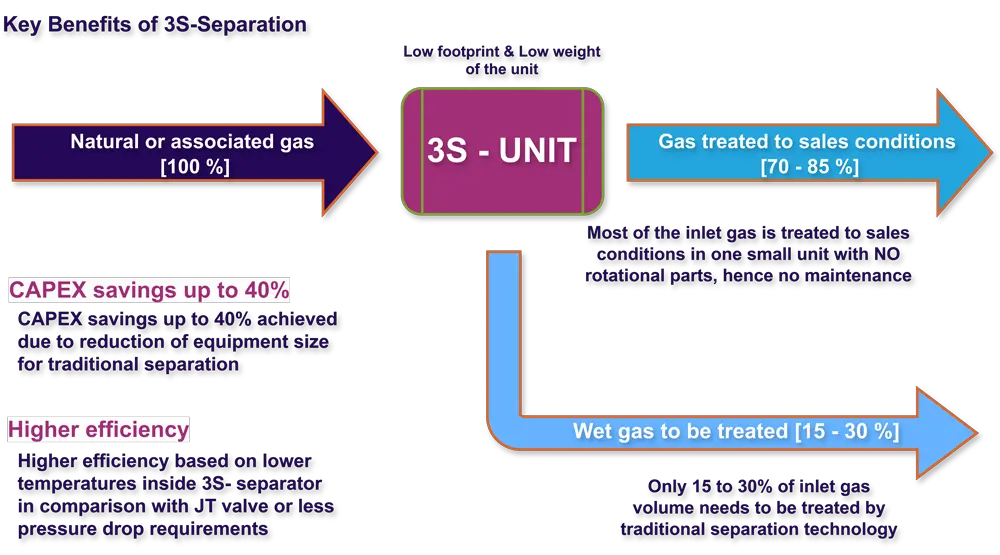

In addition to 10 years of solid contact with 3S technology, there is also more than 20 years of knowledge in the field of logistics and maritime, as well as project management skills in versatile areas, enriched by more than 30 years of experience in international business as such.