Diseño compacto y de alto impacto: la nueva generación del separador 3S

Tecnología del separador 3S: un avance en la separación supersónica de gas

Visión general del separador 3S

El separador 3S (SuperSonic Separation) es una tecnología revolucionaria para el tratamiento de gas natural y gases de proceso, que ofrece una solución innovadora, altamente eficiente y compacta para la separación gas-líquido y gas-sólido. Basado en el principio de expansión supersónica, el separador 3S utiliza dinámica de fluidos avanzada para crear condiciones termodinámicas extremas, logrando condensación y separación en un único proceso continuo y de bajo consumo energético.

El sistema del separador 3S introduce un nuevo paradigma en el acondicionamiento de gas, la deshidratación y el control del punto de rocío de hidrocarburos, permitiendo ventajas operativas y económicas significativas frente a tecnologías convencionales como válvulas Joule-Thomson (JT), deshidratación con glicol y separación mecánica.

Cómo funciona: el principio de separación supersónica

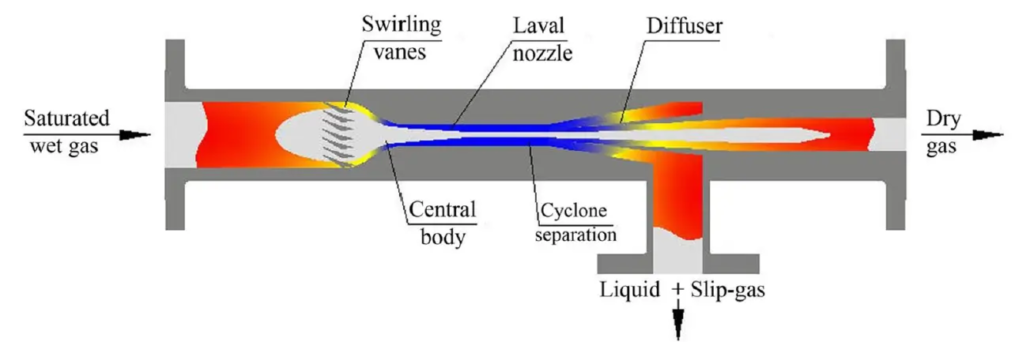

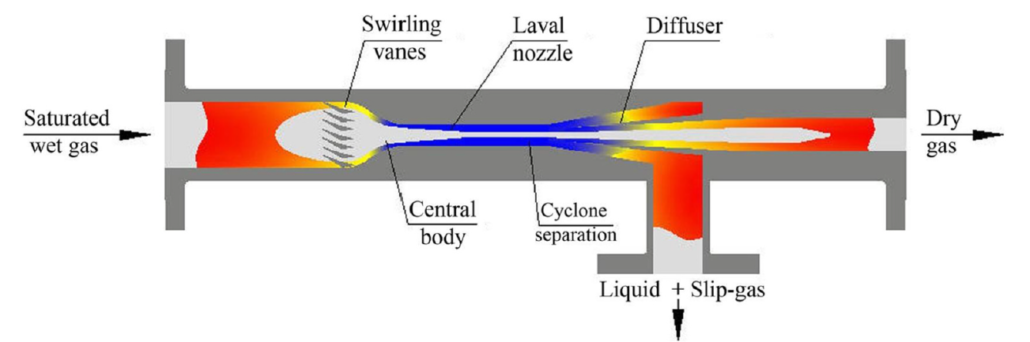

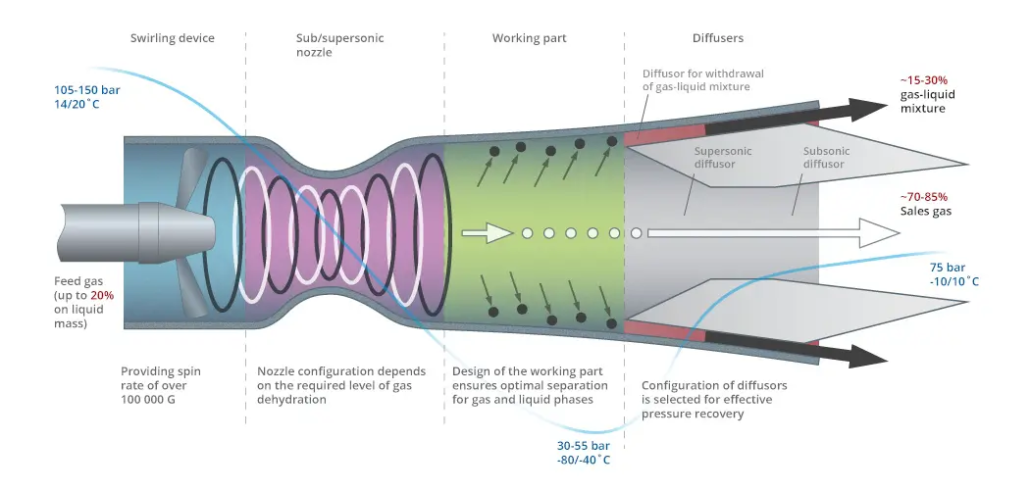

El separador 3S funciona mediante un proceso de varios pasos:

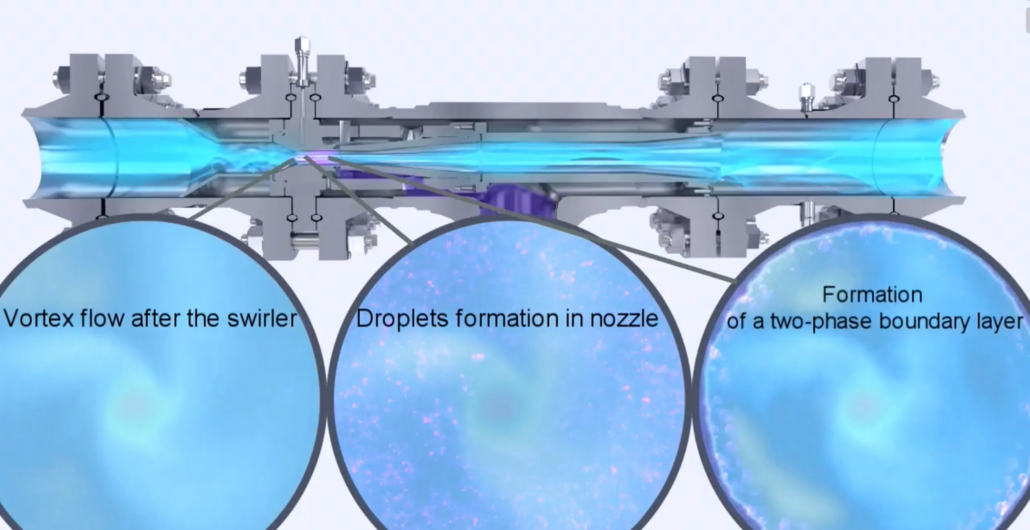

- Aceleración y expansión: el gas entra en una tobera Laval donde se acelera hasta velocidades supersónicas. Esta expansión provoca una rápida caída de temperatura y presión.

- Condensación: debido al enfriamiento extremo, los hidrocarburos más pesados, el agua y otros componentes condensables forman gotículas.

- Giro y separación: un elemento de giro imprime una alta fuerza centrífuga, llevando las gotículas y las partículas sólidas hacia las paredes y separándolas de la corriente de gas.

- Recuperación y recomprensión: el gas empobrecido en líquidos se recomprime y los líquidos y sólidos separados se extraen aguas abajo.

Esta secuencia tiene lugar en cuestión de milisegundos y sin partes móviles, lo que se traduce en una operación muy fiable y de bajo mantenimiento del separador 3S.

🔗Más => principio de funcionamiento del separador 3S

Características clave del separador 3S

| Característica | Descripción |

|---|---|

| Sin partes móviles | Garantiza alta fiabilidad y mantenimiento mínimo. |

| Diseño compacto | Hasta un 70% más pequeño y ligero que los sistemas tradicionales. |

| Eficiencia energética | Utiliza la caída de presión en lugar de energía externa para su funcionamiento. |

| Modular y escalable | Se integra fácilmente en distintos tamaños y configuraciones de sistema. |

| Respuesta instantánea | La separación se produce en milisegundos, permitiendo ajustes del proceso en tiempo real. |

Aplicaciones típicas – separador supersónico de gas

Usos habituales

- Procesamiento de gas natural

- Acondicionamiento de gas de gasoducto

- Control del punto de rocío de hidrocarburos

- Deshidratación de gas

- Eliminación de CO2 y H2S (con enfriamiento y sorbentes aguas arriba)

- Recuperación de LGN (líquidos de gas natural)

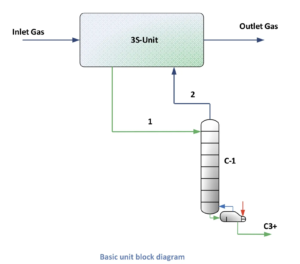

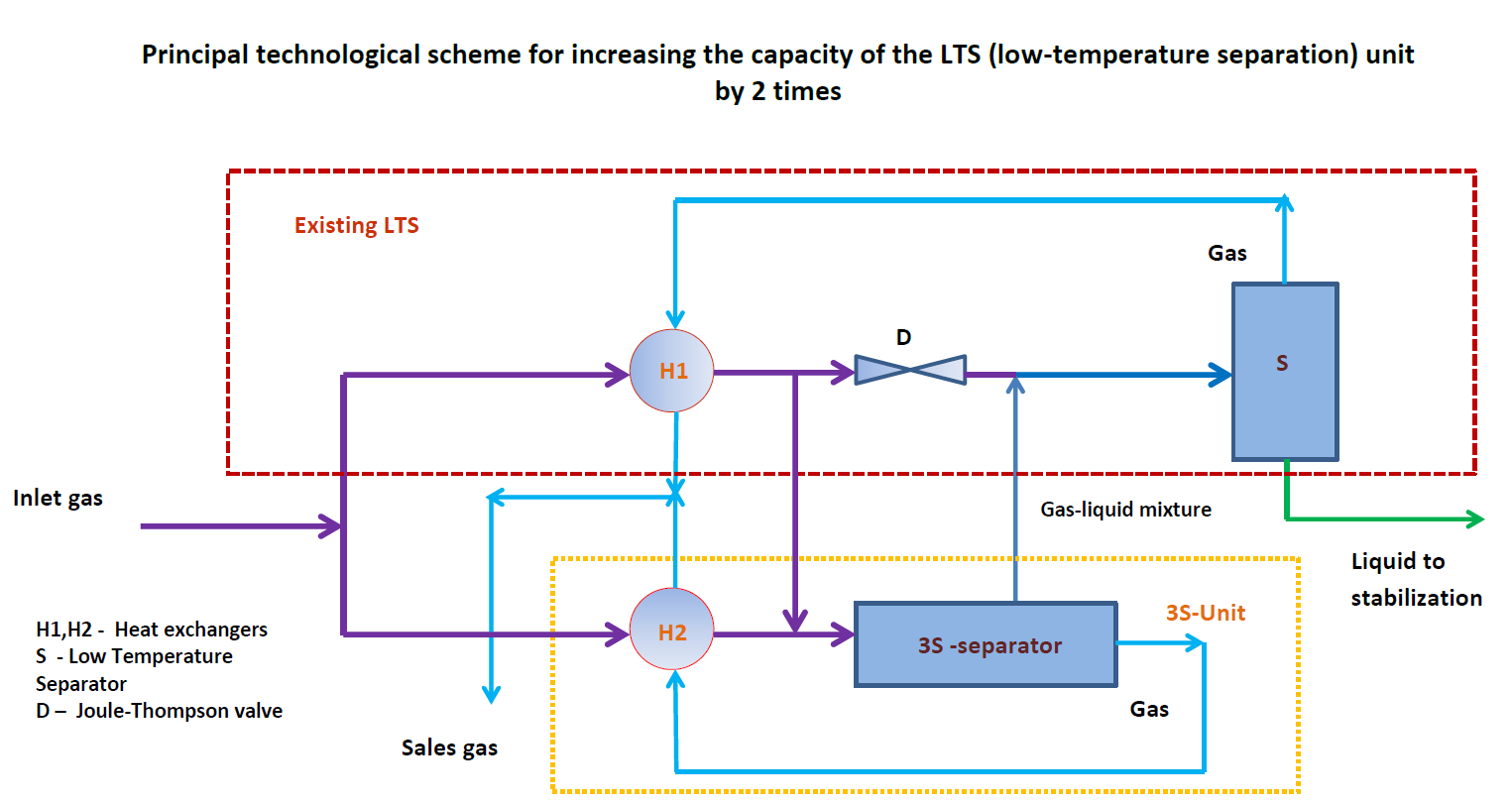

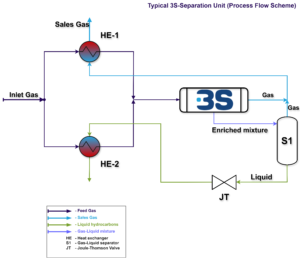

Ejemplo de diagrama de proceso – separador 3S

El siguiente esquema muestra una unidad típica de separación 3S:

- El gas de alimentación se preenfría (si es necesario).

- El gas pasa a través de la tobera Laval y de la cámara de giro.

- Los condensados se eliminan mediante una zona de separación ciclónica.

- El gas limpio, seco y acondicionado sale del sistema.

Este esquema puede adaptarse a operaciones upstream, midstream y downstream en función de los requisitos del proceso del cliente.

🔗Más => esquema estándar de flujo de proceso del separador 3S

Beneficios de la tecnología 3S

| Beneficio | Impacto |

|---|---|

| Mejor calidad de gas | Entrega gas con especificaciones de gasoducto o gas de venta sin tratamientos adicionales. |

| Menores costes operativos | No se necesitan reactivos químicos, calentadores ni compresores aguas abajo. |

| Mayor recuperación de líquidos | Alta eficiencia en la separación de LGN y condensados. |

| Cumplimiento ambiental | Emisiones reducidas y posibilidad de operación sin venteos. |

| Retorno de inversión rápido | Menor CAPEX y OPEX con periodos de retorno cortos. |

| Huella mínima | Ideal para plataformas offshore, FPSO y instalaciones remotas. |

Comparación de tecnologías & separador 3S

Comparación de tecnologías

| Tecnología | Separador 3S | Válvula JT | Deshidratación con glicol | Separador mecánico |

|---|---|---|---|---|

| Partes móviles | No | No | Sí | Sí |

| Huella | Pequeña | Media | Grande | Media |

| Requerimiento energético | Bajo | Medio | Alto | Medio |

| Eficiencia de separación | Alta | Media | Alta (deshidratación) | Baja |

| Recuperación de líquidos | Alta | Media | Baja | Baja |

| Impacto medioambiental | Bajo | Medio | Alto (uso de químicos) | Medio |

Por qué elegir la tecnología 3S

El separador 3S es una solución probada en campo y diseñada para los sistemas energéticos modernos. Ya sea que su objetivo sea maximizar la recuperación de líquidos, cumplir las especificaciones de gasoducto, reducir los costes operativos o incrementar la eficiencia del proceso, el sistema 3S ofrece una alternativa potente a las tecnologías tradicionales.

Con múltiples unidades de separador 3S operando con éxito en entornos exigentes y en aplicaciones muy diversas, la solución 3S está preparada para afrontar los desafíos del cambiante panorama energético.

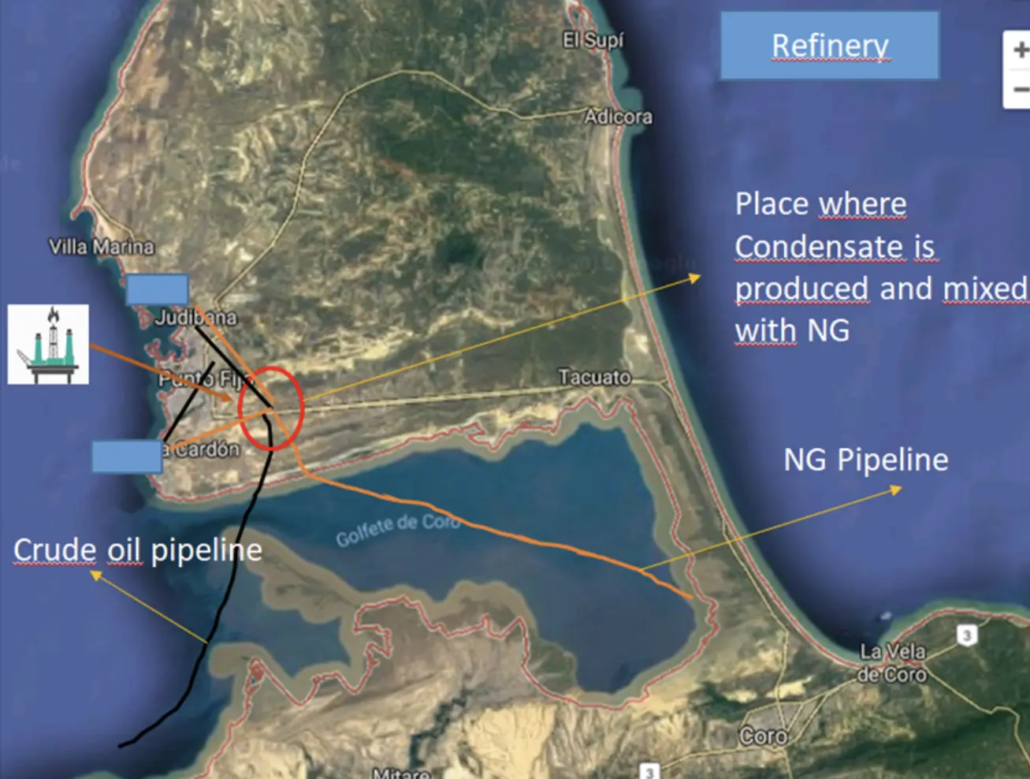

Más => proyectos de separador 3S y tecnología 3S en todo el mundo

Contacto y soporte para integración

3S ofrece soporte de ingeniería integral, desde estudios de viabilidad hasta la integración completa del separador 3S en sistemas existentes o nuevos de procesamiento de gas.

Para obtener más información sobre cómo el separador 3S puede mejorar sus operaciones, contacte con nuestro equipo o visite:

Para más detalles sobre cómo el separador 3S puede optimizar sus procesos, póngase en contacto con nuestro equipo o visite:

🔗 www.3s-most.eu

🔗 SIMETRA SERVICE S.A. Neuquén, Argentina

🔗Separador 3S – formulario de consulta